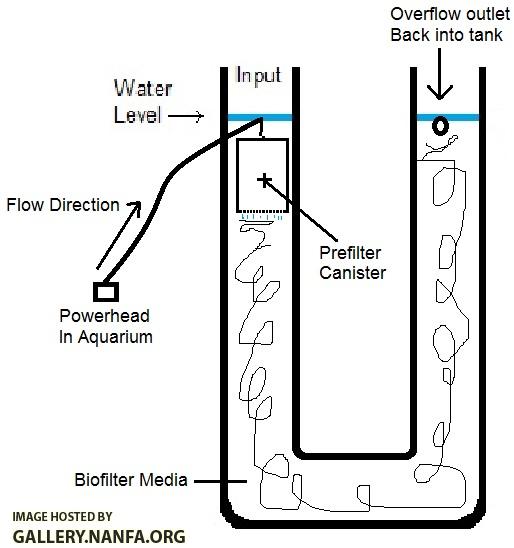

(Clog bypass not included in pic - thanks gerald)

The above picture uses 3" inch PVC with an expected water level 44 inches from the floor, or bottom of the sump. This provides a total sump volume of 2.7 gallons. This could be greatly increased with larger diameter PVC. Here is the volume tables.

Volume Table (same height 44"):

3" inch PVC = ~2.7 gallons

4" inch PVC = ~4.8 gallons

6" inch PVC = ~10.8 gallons

8" inch PVC = ~19 gallons

I am using 3" inch PVC as a demonstration because I had some extra 3" inch PVC pipe laying around and it should be big enough for the 20 gallon tank I will test it on.

Objectives:

1} Provide a large volume small footprint sump pump that can be placed behind any standard aquarium on a standard 29 inch base, or on a platform for higher tanks.

2} Remove any need for special plumbing not self contained in the sump and kept at a bare minimum making it highly portable between tanks and locations.

3} Provide the overflow on the return side to avoid the loss of priming of the siphon on standard tanks lacking a built in overflow.

4} Reduce the head pressure on the pump to near zero to maximize flow rates from any given pump.

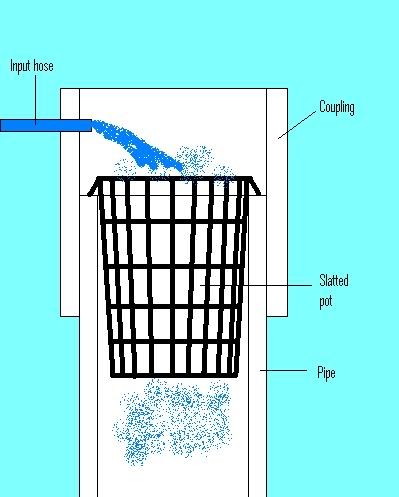

5} Provide easy access and maintenance of the primary filter without requiring the pump to be shut down.

6} Provide a range of filtration media options easily accessible and maintainable.

7} Increase the number of bioballs or equivalent the water column must pass through in the sump.

8} Provide an external self contained location to include heaters, aerators, etc.

Caveats:

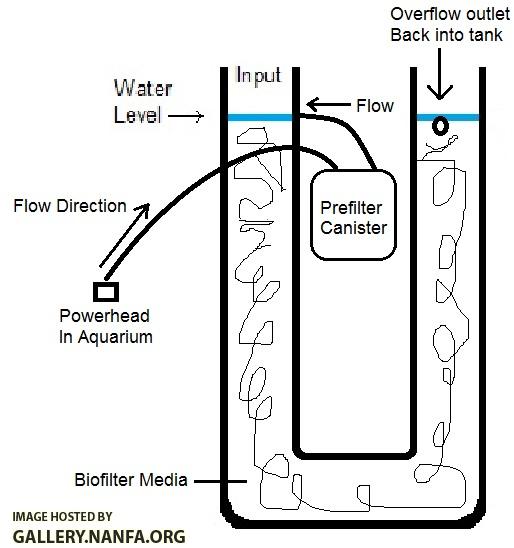

Because the water is pumped from the tank and gravity feed back in it will not maintain a constant water level as the water evaporates, but a minimum level can be maintained by limiting the depth of the pump. If it sucks air it is time to add water. If a tank has a built in overflow, or it is simply preferred, you can overflow into the U-Sump and place the pump inside the return pipe rather than the aquarium. Without a built in overflow that does not require a siphon that would require the water level in the U-Sump to be somewhat below tank level. This makes me think I should make it reversible in this way up front.

Many more features will be added later. Looks like I need to get out the chop saw because I can not find a tiny piece of my hacksaw that holds the blade on.