Stream Tank Filtration

#1

Guest_TylerW_*

Guest_TylerW_*

Posted 30 October 2009 - 04:31 PM

I am still planning on setting up the 30 gal as a stream tank. Lots of loose rocks and pebbles. Lots of current and no plants. Custom built PVC spray bar and intake. Background made from slate tiles.

I have decided on an external pump of at least 500 gph. I have found several used ones on Craigslist that fit the bill. Hoping to have one by Monday.

Now, how am I going to filter this tank? I had originally planned on using a canister filter to provide power and filtration but I don't think that will be enough umpf. A HOB would ruin the aesthetic I am looking for. Not sure about wet/ dry filters. I was planning on a simple closed loop.

If I got a canister filter could I plumb it in line with the pump? Or, would the extra pressure from the 500+ gph pump be too much? I assume that if I ran both the pump and canister filter at the same time the canister would have ~0 head.

It also seems like it might just be a bad idea. Who knows what could go wrong. Canister filters are not designed to have that much extra water run through them.

The only ways around it would be to:

A) Run the canister filter and pump in parallel with seperate intakes and spray bars.

B) Build a "wet" bio-filter that would with stand the pressure/ have a minimal amount of head.

C) Find some third filtration option (sponge, UG, in tank, no filter)

Any help would be greatly appreciated. As much as I know about fish (not enough) I know even less about plumbing! I hope the tank plumbing masters around here can help me out. Thank you for your help (again!).

#2

Guest_jblaylock_*

Guest_jblaylock_*

Posted 30 October 2009 - 04:48 PM

I don't know if you want this kinda trouble, but I suppose you could have the tank drilled and use a bulkhead(s) to remove the ugly hoses/etc... and still have the function of both a canister filter and external pump.

Also, could you run 1 large intake and have it split and one end go to the canister and the other to the pump. This would rid you of one extra intake and wouldn't overrun the canister filter. You could join the two back into one before entering the tank, but I would think the 'suction' of the outflow from the pump would speed the water through the canister.

just tossing a few ideas out there.

Josh

#3

Guest_Newt_*

Guest_Newt_*

Posted 30 October 2009 - 05:14 PM

Advantages of sump-

You can make it as big as you want it, and stuff it with whatever types of filter media you like. It is endlessly customizeable and modifiable. It increases water volume in the system. Maintenance is easy. You can add a refugium- great for growing scuds and other foods. Can be made cheaply if you don't mind a little work.

That work is the major disadvantage. You also have to be careful with design to make sure it won't overflow in case of pump failure.

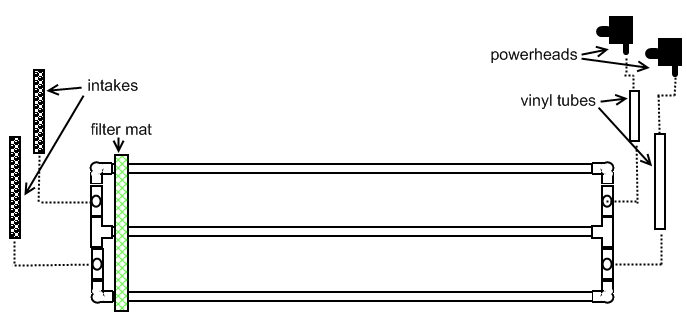

You can also make a stream tank with no external filtration. I am testing a design on a 55 gallon tank that combines the "river mainfold tank" popularized by hillstream loach keepers with a Hamburg mattenfilter. Right now it's just hardware in the tank, no decor; I'm getting good flow in one direction along the upper 2/3 of the water column, with a backcurrent restricted to the bottom, which I hope can be broken up with decor. Besides the price of powerheads the other components are inexpensive and readily assembled- PVC pipe and fittings, a little vinyl tubing, and a sheet of pond filter mat ("Jap mat") big enough to cover one end of the tank. You can paint the exposed PVC to hide it, and the mat will quickly become dingy and algae-laden, disappearing into the decor.

#4

Guest_TylerW_*

Guest_TylerW_*

Posted 30 October 2009 - 11:01 PM

You can also make a stream tank with no external filtration. I am testing a design on a 55 gallon tank that combines the "river mainfold tank" popularized by hillstream loach keepers with a Hamburg mattenfilter.

This idea is the kind of solution I was hoping to find. I was already planning on covering the in take with a sponge filter or filter batting. What I am visualizing now is a "manifold" design but simply placing the pump outside the tank. I think this has 2 benefits: less heat exchange and aesthetics. But, the basic idea and construction will be similar. Now I am trying to think of a way to incorporate an in-tank filter into the decor and intake design.

I really want to go to great lengths to make my tank look like a section of riffle sitting in my living room. One idea I had was to hide my spray bar behind some slate. First I would use foam to fit around the spray bar and make a ~1.5" x ~1.5" block ~12" long. Then, using a wet saw, cut 2 pieces of slate tile to fit on the exposed sides. I would use a small masonry bit to drill through the slate and then lastly a wood bit to drill holes in the pipe. The idea being that the water would look like it came right out of the rock! Sure, it is a lot of futzing around... but its nearly winter here. I need something to keep me from going crazy.

#5

Guest_miketron75_*

Guest_miketron75_*

Posted 31 October 2009 - 10:35 PM

#6

Guest_GreenLakeYak_*

Guest_GreenLakeYak_*

Posted 01 November 2009 - 12:04 AM

I don't think I'd like the look of white pvc in the tank, I know there is yellow, but black/gray would look the best I think.

Also, I was thinking of using a horizontally oriented intake filter, keeping it just above the gravel/sand to keep it the least visually obtrusive as possible. Like this, and using a cylindrical sponge filter fitted over the intake bar, and no filter pad.

Edited by GreenLakeYak, 01 November 2009 - 12:06 AM.

#7

Guest_Newt_*

Guest_Newt_*

Posted 02 November 2009 - 10:00 AM

GreenLakeYak- Cylindrical sponges are probably functionally the same as the mattenfilter. The filter mat provides more surface area, so it is more resistant to clogging. I also like the look of a "false wall" better than the look of two cylindrical intakes. Most importantly, I already had a sheet of filter mat

What I would worry about with your design is the small size of the intake area- the smaller it is the more prone it is to clogging, which besides reducing flow may also put some unnecessary strain on your powerheads. I would at least place the intake bar so that it spans the full width of the manifold. If you can find three-way elbows to use at the rear corners that would make it easier. You might also consider a second bar.

If you are using a reasonably coarse gravel, you could even dispense with the separate intake bar and just drill holes in the manifold itself at the intake end, place some sponge or filter mat over the intake, and pile your substrate atop the filter media. I wouldn't do this with sand though.

#8

Guest_TylerW_*

Guest_TylerW_*

Posted 02 November 2009 - 03:51 PM

How hard is it to build an overflow and sump? To me a sponge or matten filter seems like the simple solution. In my case I would probably use one or two sponge filters placed horizontally in the tank right at (or slightly above) the substrate. By placing them horizontally they could be 12" long with out obstructing the field of view. Not really hidden, just low profile.

I saw one example where a river manifold used a section of UGF on one end for the intake. This seems like the least visually obtrusive option but also the hardest to maintain. I don't really like all the food getting sucked down into the gravel where it is hard to clean out.

I had thought about a "water fall" style filter. In fact the plans are still safely in my head. Maybe you could call it the "Reverse Matten". Water pouring into the tank over some bio filtration media and then flowing out through a screen. My concern was designing it so that the filter media/ manifold/ and "screen" allowed a high volume of water through.

I still like the idea because the closed loop designs seem to have less chance of a catastrophic tank draining....

#9

Guest_Newt_*

Guest_Newt_*

Posted 02 November 2009 - 04:20 PM

It is easy to prevent catastrophic tank draining. You just need to design the overflow/standpipe/what have you so that it only drains the tank to a certain level. With a standpipe this is simply a function of standpipe height; with a siphon overflow it can be accomplished by drilling a hole somewhere on the pipe that will allow air to enter and break the siphon when the water level drops to it. Then you must figure out the volume of water that will be drained and make sure your sump has enough extra volume to accomodate that water.

If you build a closed-loop external version of the river manifold, you're 3/4 of the way to building a canister filter. You may as well just buy a high flow canister, in my opinion.

The external pump/internal filtration combination just doesn't make sense to me. The major reason to use internal filtration is to avoid the hassle of setting up an external pump, so if you are going through that hassle you may as well use external filtration.

#10

Guest_GreenLakeYak_*

Guest_GreenLakeYak_*

Posted 02 November 2009 - 07:17 PM

GreenLakeYak- Cylindrical sponges are probably functionally the same as the mattenfilter. The filter mat provides more surface area, so it is more resistant to clogging. I also like the look of a "false wall" better than the look of two cylindrical intakes. Most importantly, I already had a sheet of filter mat

.

What I would worry about with your design is the small size of the intake area- the smaller it is the more prone it is to clogging, which besides reducing flow may also put some unnecessary strain on your powerheads. I would at least place the intake bar so that it spans the full width of the manifold. If you can find three-way elbows to use at the rear corners that would make it easier. You might also consider a second bar.

If you are using a reasonably coarse gravel, you could even dispense with the separate intake bar and just drill holes in the manifold itself at the intake end, place some sponge or filter mat over the intake, and pile your substrate atop the filter media. I wouldn't do this with sand though.

I whipped up that image quickly, in reality it would be a bar that is nearly the width of the whole tank like you said. I thought about this a bit, but with my design you would have to disassemble the pvc just to remove the sponge to clean. A better version like in the image I posted below.

I think like the idea of the lower-profile horizontal bars instead of the vertical ones, good idea with drilling holes directly in the manifold. I think drilling holes only on the top 1/4 of the bar would work best, that would allow you to put substrate on the bottom and sides of it, and then cover the top with loosely packed gravel to mask the bar. However the problem with that is that I don't see a good way in securely mounting the filter mat or sponge mat other than laying it on top and covering it with gravel or rocks.

I'll probably just do a revised version of this.

Edited by GreenLakeYak, 02 November 2009 - 07:39 PM.

#11

Guest_TylerW_*

Guest_TylerW_*

Posted 04 November 2009 - 08:57 AM

If you build a closed-loop external version of the river manifold, you're 3/4 of the way to building a canister filter. You may as well just buy a high flow canister, in my opinion.

Originally I had planned on doing just what you suggest. But, the highest flow canister I could find was measly 350gph. So, when I found a used Little Giant 4-MDQ-SC for $20 I couldn't turn it down. Accounting for head this pump should still give me at least 700 gph. It has a shut off height of 24 feet, so it should have plenty of power to overcome a spray bar. Once I get the plumping in place I will post pics or video and report on its performance.

The plan right now is to get the current producing pump and plumping put in place and worry about filtration second. I am not planning on collecting fish until spring so I should have plenty of time to figure out the filtration part of the equation.

#12

Guest_TylerW_*

Guest_TylerW_*

Posted 18 November 2009 - 09:20 AM

Believe it or not, this post wasn't even supposed to be about the spray bar. It was supposed to be about slate tile.

I have coveted Skipjack's slate tile background since I first laid eyes on the pictures.

http://forum.nanfa.o...__slate__st__20

Does anyone have ideas on how I could safely install slate tiles as a background in a glass tank? Should I try and support under the glass? Distribute the weight over the inside of the glass? Will gluing the slate to the back of the tank support any of the weight?

Or should I not worry about the extra weight? Having a 30 gallon tank I would need 16" x 16" tiles to go from top to bottom. They seemed pretty heavy at the store...

One last idea I had was using fake vinyl tiles. After they are covered in algae they would look realistic enough (and easier to work with) but not heavy at all. Any chance that they would de-gas and kill everything in the tank?

#13

Guest_TylerW_*

Guest_TylerW_*

Posted 23 November 2009 - 01:12 AM

But, my pump is making a lot of noise. I am thinking that I need to do a better job of dampening the vibrations. My other thought is that there maybe something in the impeller - possibly a pebble or bit of sand. Of course taking the pump apart to get at that would be fun. Anyone have any experience taking the little giant pumps apart? Or, more importantly putting them back together?

Sorry for the late night ramblings. Work on tank till midnight - post latest problem.

#14

Guest_TylerW_*

Guest_TylerW_*

Posted 04 March 2010 - 12:48 PM

I need help. How does everyone deal with pump noise? I added rubber stoppers in between the pump and the stand and it was still too loud (louder than the TV). I tried encasing the pump in a box with several layers of cardboard to see if sound proofing was possible. It took the edge off, but not enough. Has anyone had any luck soundproofing a tank stand?

At this point I am not optimistic about saving the little giant. I am getting between 600 and 700 gph, and I actually think I would like more. I am going to re-work my plumping to take out several 90's. I think I can get the head down to around 6' or 7'. What is recommended for a quiet pump that can do 800 gph at 7'?

I am thinking about the Mag 12? Are they quiet enough to run in the living room?

Thanks again.

#15

Guest_lozgod_*

Guest_lozgod_*

Posted 04 March 2010 - 03:43 PM

Here is the powerhead on one end.

On the other end is a sponge.

#16

Guest_TylerW_*

Guest_TylerW_*

Posted 08 March 2010 - 03:22 PM

Actually, I should say that my theory is sound. The external pump is producing huge amounts of current with out adding heat to the water. But it has a few bugs to be worked out.

In a flurry of activity I installed a ball valve on my out flow, replaced two 90's with a section of 1.25" ID tubing and upgraded the inflow to 1" ID tubing. At the same time I took apart the pump and cleaned it. The pump came apart easily and revealed tons of calcification. Obviously the pump had been running rough for some time as there are grooves on the impeller. There was even a pebble cemented to the front of the impeller. So, as suspected, it did need to be cleaned. And now it runs much much quieter. But it is not quite quiet enough. (How do you know when to replace impellers?)

At this point I noticed gurgling/ cavitation in the outflow pipe. It seems to be coming from the top of the siphon where two 90's make the U-turn. Despite the fact that the Little Giant has a 1" inflow the 1" pipe/ elbow is not really large enough to handle 850gph. This never really occurred to me as I assumed that the pumps inflow would be the same size as the pipe needed to feed it. Well... you know what they say about assuming...

When I put my thumb over the inflow the pump runs quieter and the cavitation nearly ceases. So, I have a couple options.

1. Run the pump with a valve restricting the out flow.

2. Cut out the two 90's at the top and replace them with an 1.5" - 2" PVC U-turn (sink trap with clean-out).

3. Drill the tank and install a bulkhead.

Option #1 is not really an option. I would still like to run this wide open. #2 could be done in about 20 minutes and cost $10, but I am not sure if it would work. Which would leave me redoing all the plumbing and trying option 3.

This site lists the recommended suction velocities for a given pipe size. A 1" pipe running at 1.5 ft/s will only deliver 220 gph. To get over 850 gph, with out exceeding the recommended velocity, I would need a 2" pipe...

Can I really drill a 3" hole in my tank? If I have a shorter run with only one elbow (leaving the bulkhead) do I really need 2" pipe all the way to the pump?

It seems I am learning most of this by trial and error.... mainly error.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users