I installed my background into the tank last night with silicone. I faced several issues that I had to deal with that have bothered me since I finished the construction of this beast, and two issues that I hadn't thought about. The issues were:

1) I used enough foam board and spray foam when constructing this background to float my boat, and needed to use a ton of silicone to keep it from ripping away and floating.

2) Because this background fits tightly when fitted into the tank, you have to slide the last section in to get everything to fit, so, I couldn't silicone one section at a time in place. I needed the silicone to remain uncured and wet during the process.

3) How exactly could I accomplish physically solving the two problems above without making a mess.

4) While applying the silicone, I wasn't sure if I purchased enough tubes, and it was Thanksgiving afternoon, and finding a store that was open to sell them to me was a problem. Not only that, we had family plans, and time for me to work was limited.

5) The silicone fumes were intense.

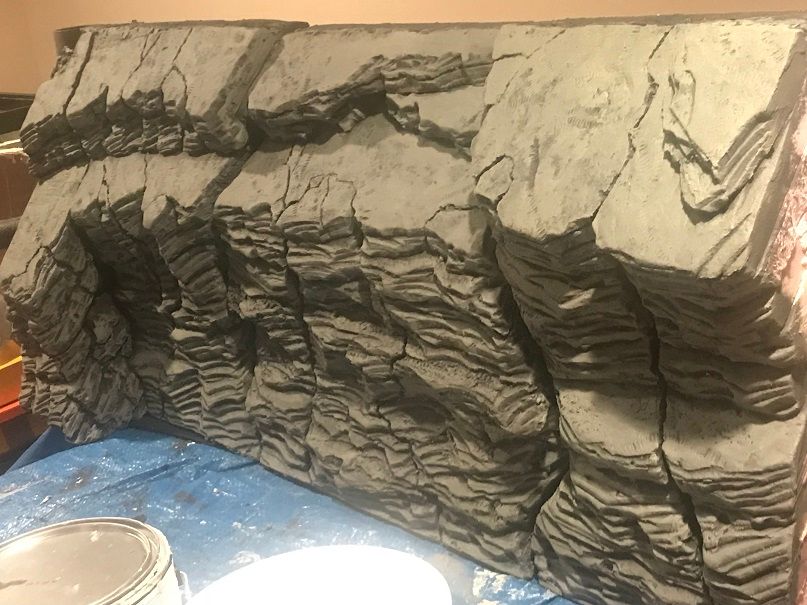

Below are pics of the process, and explanations on how I dealt with each issue.

First, I cleaned the tank and drew lines with a sharpie of approximately where I needed to apply silicone directly to the glass.

Issue #1: Applying enough silicone to keep it from breaking away and floating. I applied silicone directly to the glass, then to the back and bottom of each background section. I cut each tube to allow me to apply a thick bead of silicone to each surface. On the backgrounds, I focused on areas that may not make contact with the glass, thinking that the silicone on the glass and in a given crevice would make contact and bond, and the areas that made direct contact with the glass would have sufficient silicone from the amount that I applied to the glass.

Issue #2: Solved by installing everything as soon as possible. My only mistake was applying silicone to the right side of the last section. I should have applied a thicker amount of silicone directly to the glass, so that when I slid the last section into place, it wouldn't make a mess. Issue #3: I left enough room on the edges of the structure to be able to lift and maneuver each section into place. This also kept most of the silicone out of sight.

Issue #4: Solved, because I barely purchased enough. I went through 7 tubes. Using a very thick bead causes you to go through each tube much quicker than you would for household applications.

Issue #5: My entire rec room still smells of silicone. I had a really tough time after installing the first section, especially reaching over the tank. The fumes were intense. I had to turn away, take a deep breath of fresh air, then hold my breath while working in the tank the rest of the time. I opened the door to the outside, and that, at least, allowed me access to some fresh air. It didn't help inside the tank though.

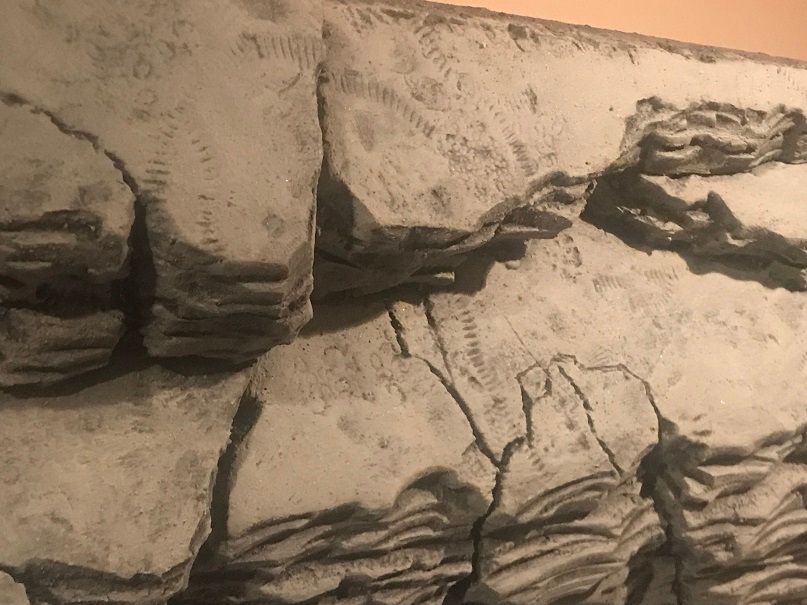

In the above pic, you can see the mess that I created while sliding in the last section of the background. It's not a big deal. I'll take a razor blade to it after it cures. Here's a closer look of the mess:

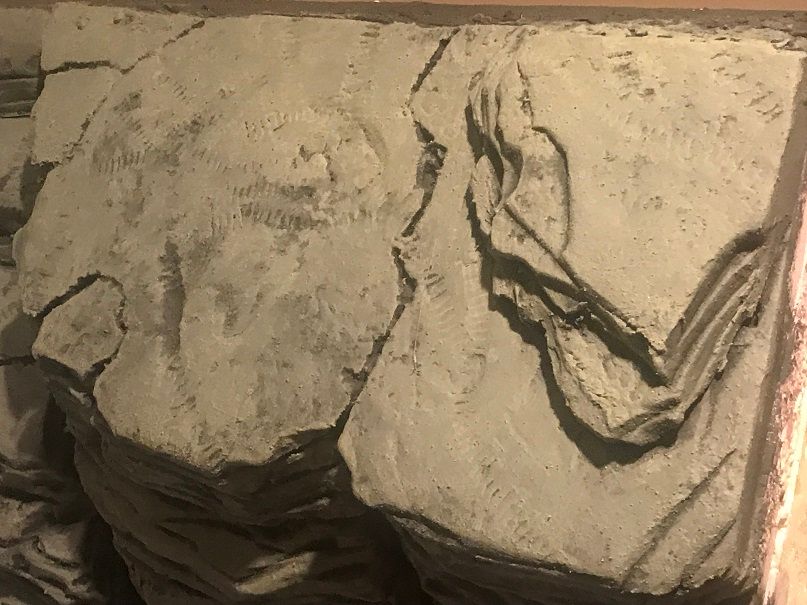

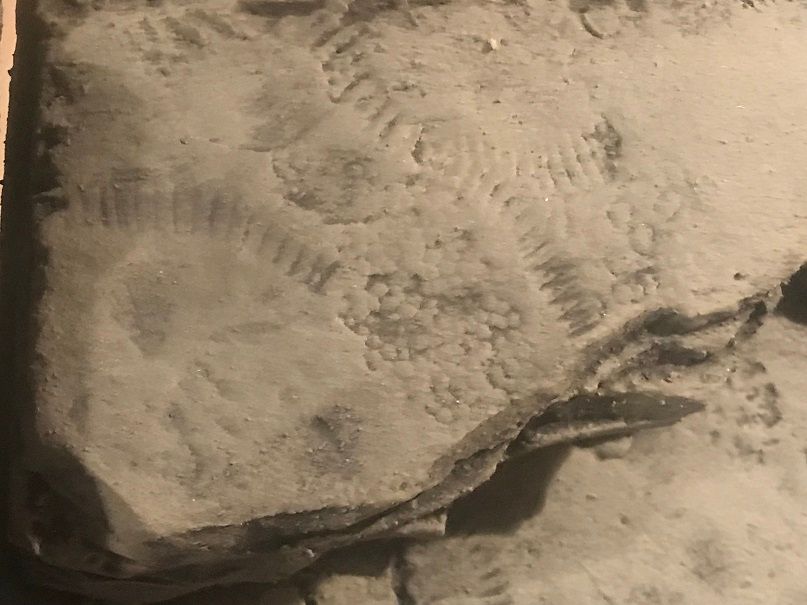

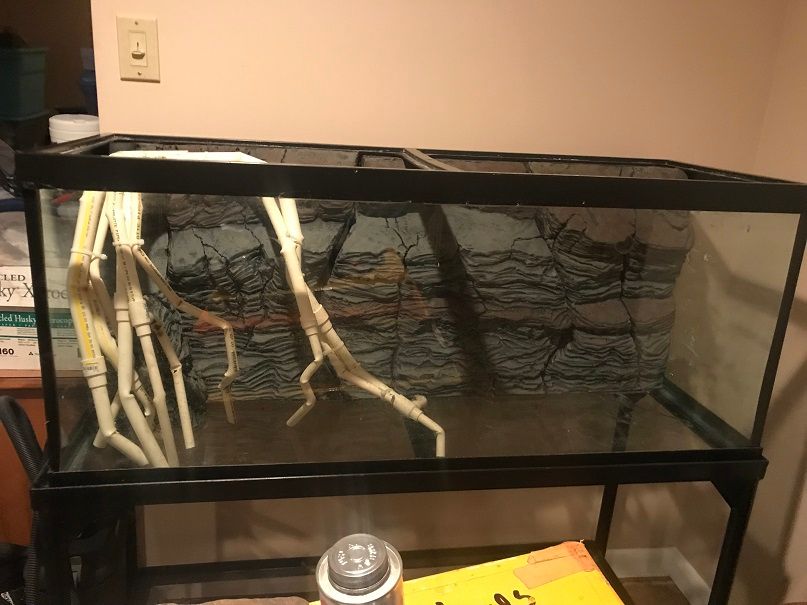

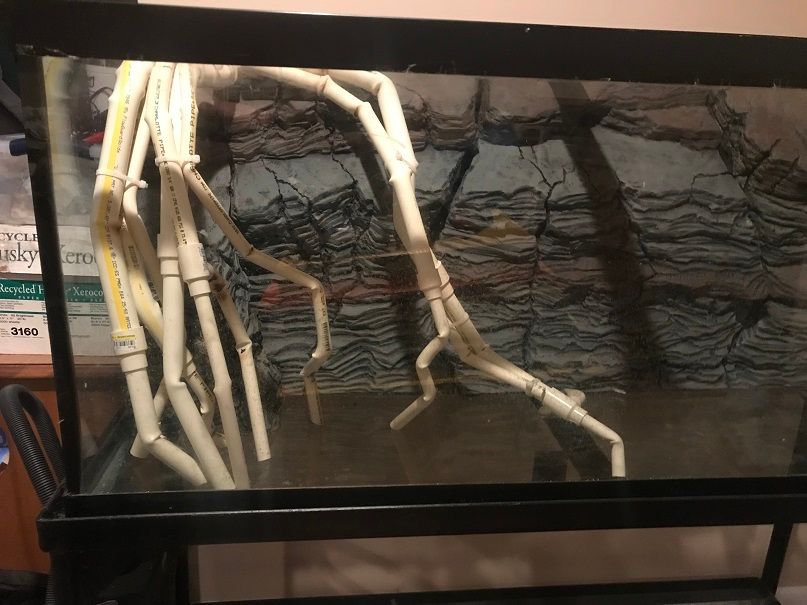

After gluing it all in place, and pressing it as firmly as possible against the glass, I installed the removable piece for a pic of what is should look like once the tank is up and running:

Next steps:

I need to paint the glass on the sides and back where the background meets the glass, to hide the ugly silicone work. There is a gap between the first two sections where light passes through. Painting the back of the tank should hide that and make it look like a natural crevice. There is a gap on the lower part of the left side that I may have to deal with. I haven't decided if I'll apply a little foam there and carve it back, and paint it, or just leave it as it is. It bothers me though (you can't see it in this pic), because the silicone shows through there and looks unnatural.

I'm going to give this some time, about three weeks, to completely cure. Then, I'll fill the tank and test to see if the installation and glue holds up enough to move forward. I'll leave it filled for 24 hours. If it doesn't rip away and break the glass, and flood my basement, then, I'll move ahead. I am fairly confident that it will be OK.

I will begin working on the fake roots. I trashed what I had done so far...didn't like it. I have a plan though. In the meantime, I need to head to the river and start collecting rocks, gravel, and sand to hardscape the tank and get it ready to set up. Once I do that, then I'll set the tank up. The roots will be installed after the tank is up and running, unless I can finish them earlier than planned.

As far as substrate goes, I would like to grow stargrass at the right third of the tank, so my bottom layer of substrate will be dirt to provide nutrients for the grasses. Sand and gravel will go over top of that.

The thought of installing this thing posed some issues and was a source of my procrastination...the thought that it wouldn't work had occurred to me. Yesterday, I woke up determined to move forward. I'm glad that part is behind me and my stress level is way reduced.

After the tank is cycled, then the fun part begins...collecting and stocking.