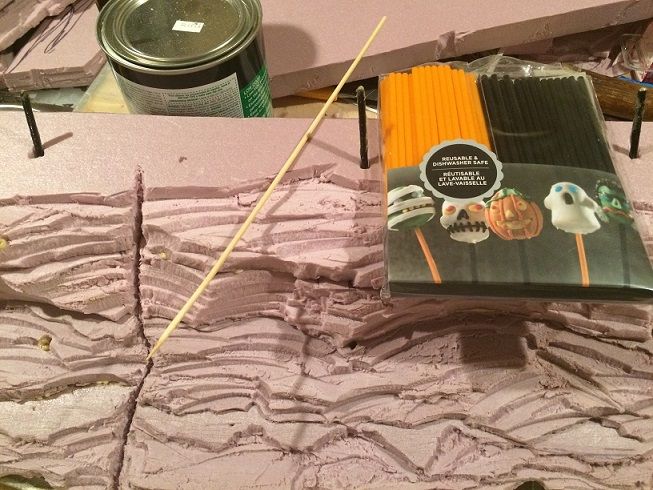

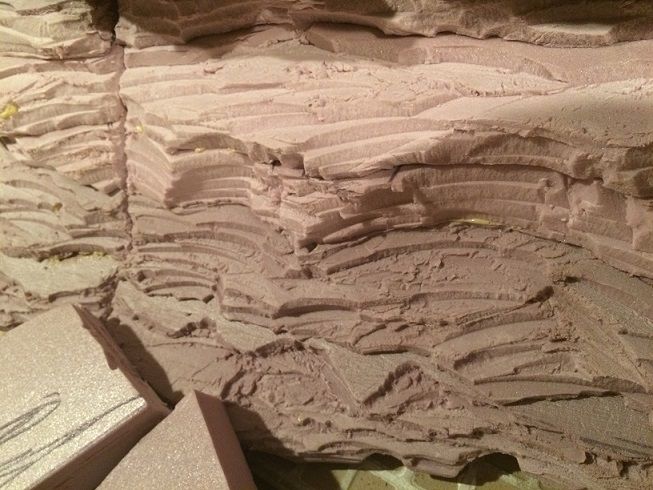

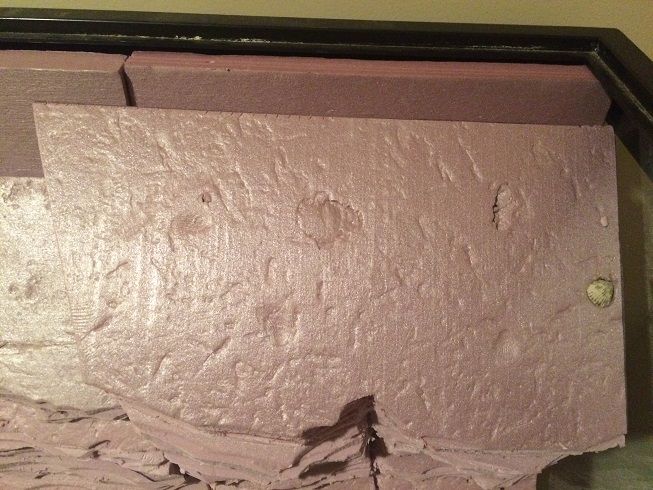

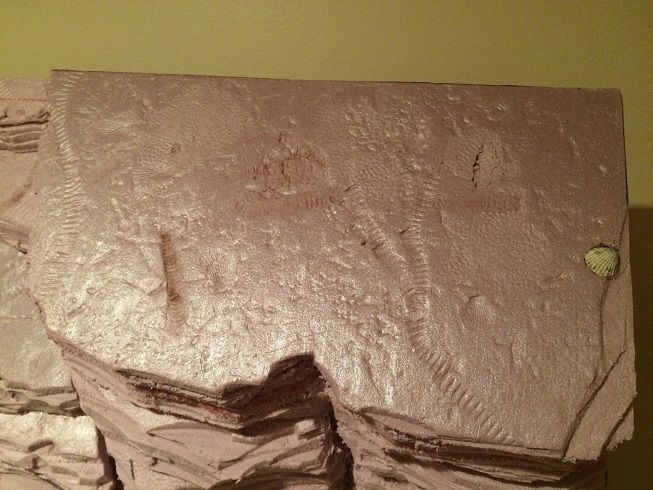

And now some experiments and results that I spoke of earlier. I tried some things on foam board pieces to see if I can get even more realism. Previously, I found that by pressing concrete stuff that I made for another purpose or stream rocks produce cool internal molds of those rocks in the foam. So my next experiment was to try and emulate fossils. I found that by cutting a section of a ribbed plastic worm and adding heavy weight on top of it resting on the board created a pretty cool effect, emulating a Devonian crinoid stem. I'm still experimenting with this concept to see if leaving it for 24 hours makes for a larger internal mold. I am not sure, but I suspect that the soft plastic might "melt" the foam in a favorable way. I'll post results tomorrow.

I tried this concept with a small clam shell found from the Chesapeake Bay and it looks pretty good. I think that I may try a large section of Devonian rock full of brachiopods to get an entire rock fossil effect. The rock that I have in mind is plenty heavy, but I'm hoping that if I add weight that it won't destroy my fossil specimens. But, if it does, then it gives me more incentive to go fossil collecting again  . I'll post results of that experiment when I'm done. If that works, then I may use that foam board as my top section or faux rock for added realism.

. I'll post results of that experiment when I'm done. If that works, then I may use that foam board as my top section or faux rock for added realism.

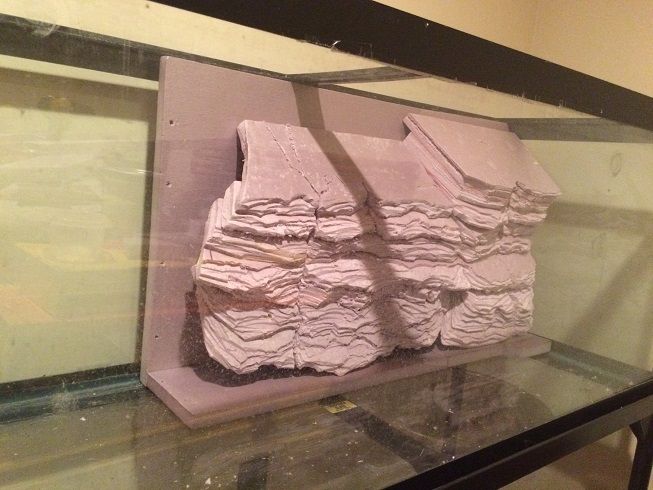

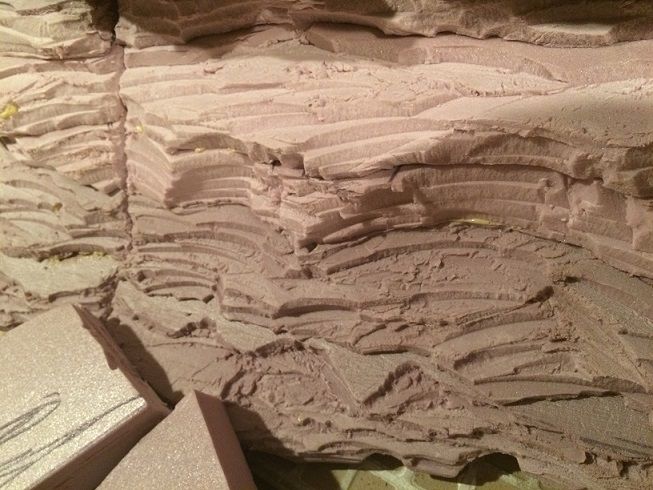

The cool thing about these experiments is that if I can achieve that realism of rock and fossil rock impressions, along with my attempts at carving, when applying the Drylok/cement dye mixture, the textures of the foam board and any work done on them will show through. That's why I didn't go with a cement coating (and also because those tend to chip away and don't show the level of detail from foam carving and other work that direct Drylok coating does, plus there are pH issues that you have to worry about with using concrete).

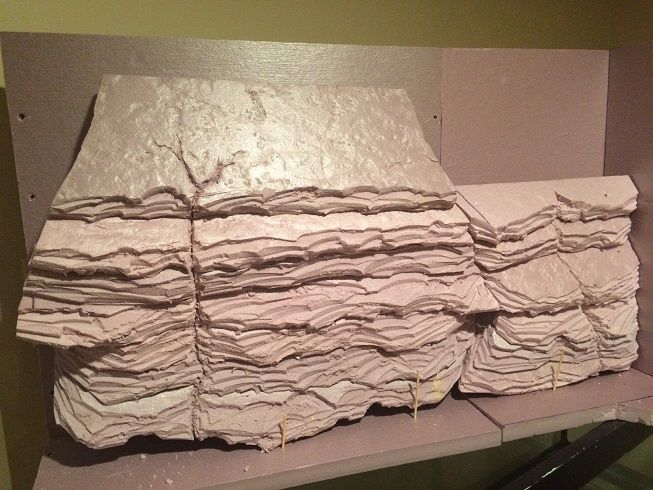

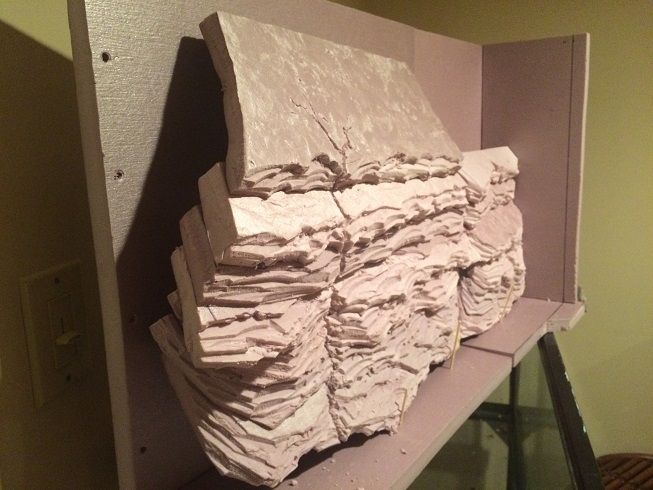

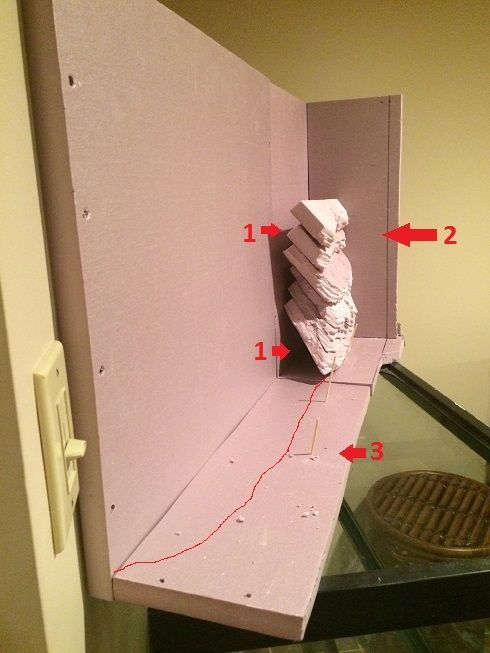

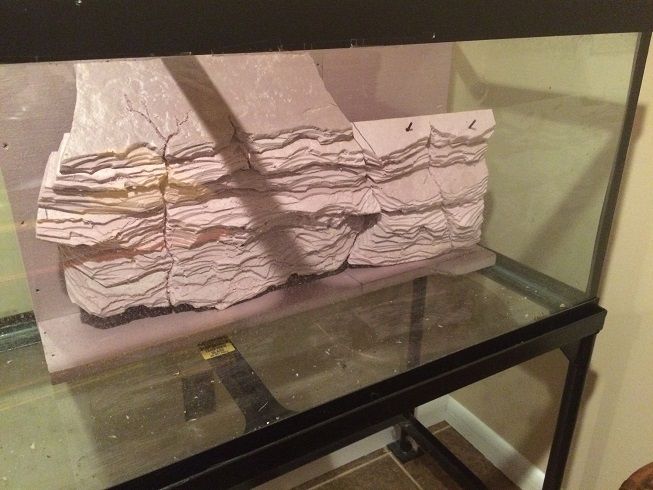

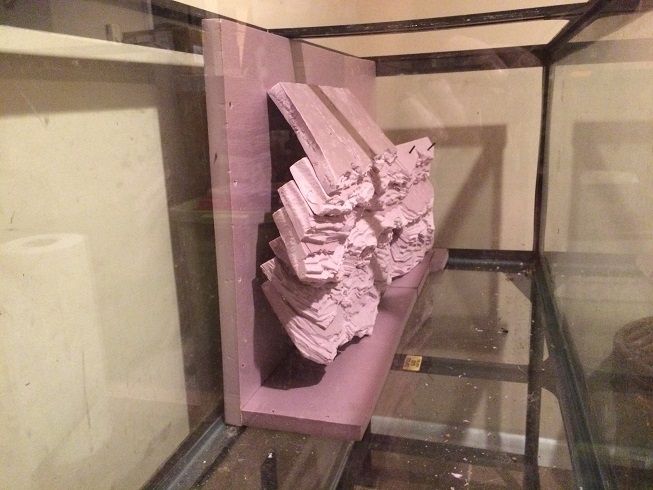

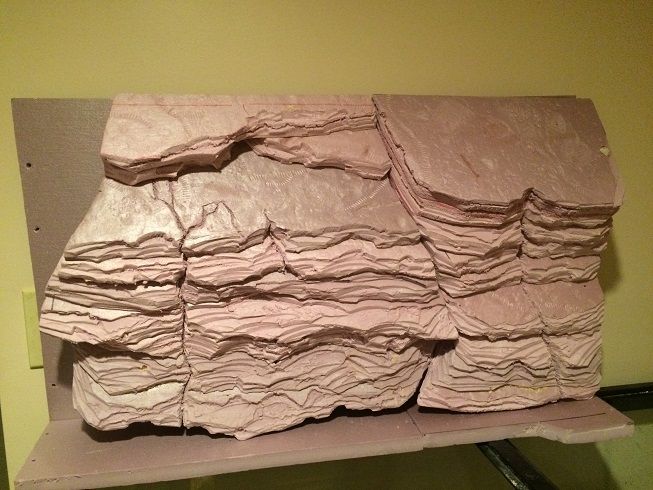

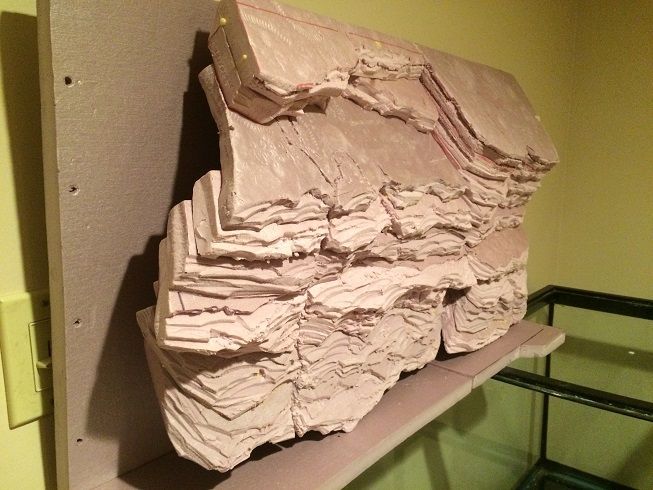

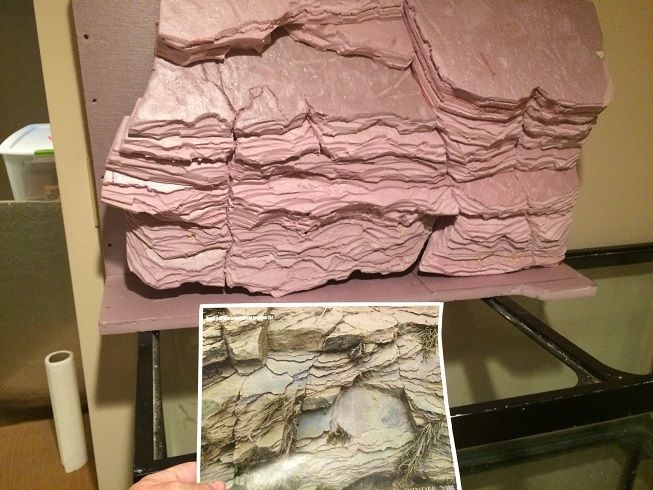

Finally, a picture along the way of the structure after gluing. I will have to chip or carve away glue that expanded between foam layers. But, I'm satisfied that the amount of weight that I'm using to press the foam boards together is resulting in very little space between boards, adding to the "one rock" realism.

33

33

I hope to have everything that I carved glued together into their respective structural sections by the end of the weekend or sooner. Then, I can proceed with more carving and working on that third section (more faux cliff rock along with an undercut bank and roots). I'm starting to get excited about how it's turning out.

By the time I finish the background, then it will time to move forward with setting up and cycling the tank. Those steps include collecting "live" substrate in the form of sand an gravel from the stream that I plan to emulate along with additional rocks. Assembling all equipment into the background so it is hidden by the faux roots and/or faux rocks. Then, filling with water and cycling. By then, I'll be ready to collect the tank inhabitants. My goal for collection time would be late March or early April.